"Epoxy Guru"

"How To" help

Epoxy help and information

Return to home page - index of other help projects page

MCU coatings for Auto Restoration

What is an MCU Coating?

Aluthane (tm) is an MCU coating. MCU stands for Moisture Cured Urethane and makes a very superior high performance coating. These are a unique type of coating much better known in commercial industrial painting circles than within the general public market. Most MCU coatings use tiny aluminum flake as pigment which gives them their classic silvery/gray color and enhances their remarkable properties.

MCU contain lots of solvents which aids in penetrating tiny cracks and crevices. The coating scavenges moisture from its contact surfaces and the air and undergoes an cross-linking molecular process which 'grips' or grabs onto surfaces for outstanding adhesion, even with poorly prepared surfaces. Removing internal surface moisture removes one of the key components necessary for rust development.

The resulting dry surface (aided by the stacking aluminum pigment platelets) provides a physical barrier to air and oxygen, another necessary component for rust to form. The result is a thin, hard coating that seals our air, water, salts, minerals etc. essentially encapsulating the surface It therefore is one of the best, easy to apply, rust and corrosion control coatings.

Its amazing adhesion results in a versatile coating well suited for use on steel, aluminum, concrete, fiberglass, wood etc. It can be used as a primer/sealer, a middle coat or a exposed as a topcoat. The aluminum pigmented versions have no UV issues, can be applied at low temperatures and operate at temperatures of up to about 400 degrees F. Besides being used as a rust stopper is also has applications on boats, roofing and flooring applications. In is used a lot in the industrial, automotive, marine and farm marketplaces. The AUTO RESTORATION market is one place these coatings are widely promoted within the 'DIY home' marketplace.

Basic MCU properties

* minimum surface prep required (so common on structures and objects hat cannot be sandblasted etc.)

* easy to apply - thin, with good coverage

* fast drying

* long life (some vendors claim 10-20 years of performance)

* very good chemical, temperature and abrasion resistance

* replacement for galvanized surfaces and other environmentally damaging zinc rich products

* contains no dangerous lead, zinc, chromates, or heavy metals

Commercial vs. DIY MCU Coating Products

Given the outstanding and time tested performance and properties of MCU coatings in serious commercial setting it is not surprising that companies have attempted to move this product into the DIY/Home-Boat Owner market. This market is less knowledgeable and will accept lesser quality and overpriced MCU coatings compared to the commercial/industrial marketplace.

Warning Flags:

* Very slick web sites that suggest their product is unique and one-of-kind and that you cannot find anything even remotely similar. Some sites really play up MCU chemistry, others hide it, thus implying how 'magical' and special their standard MCU coating is.

* Fancy product names and colorful labels that suggest a Madison Ave focus rather than no-frills commercial roots.

* Prices in the $150-$200 a gallon range. No MCU coating is that expensive to manufacture, especially for large companies. These folks are making $100 plus profit per gallon from you (with 'discounts' and 'free shipping' making hardly a dent in their profits). No commercial user would pay these outrageous prices for a gallon of an industrial coating.

* Check product coverage. These are thin products, due to their chemistry they don't need to be thick. But the general public usually thinks thicker is better. The thicker the product the more you use and the more you will have to purchase (at those extremely high prices). If coverage numbers are given make certain they are real life numbers and not "theoretical coverage" numbers. The theoretical coverage for 1 gallon of water at 1 mil thick is over 1600 square feet.

* One thing that cannot be easily established, but should be lurking in the back of your mind is the polyurethane resin used in the manufacture of the coating. Top-of-the-line, commercial/industrial MCU coatings, like our Aluthane product, use 100% polyurethane resin. MCU coatings can be manufactured with diluents and other low cost additives to reduce the amount of polyurethane resin in the manufacturing process (like adding water to the whiskey!). The result is still a good MCU, but not a great one and not one formulated for maximum performance, but rather for better profits. One of our 'regular' 30 gallon a month Aluthane MCU customers stopped purchasing for about 5 months, presumably testing alternative products. They returned to us most likely because of the higher purity/quality and reasonable price of our Aluthane (tm) MCU.

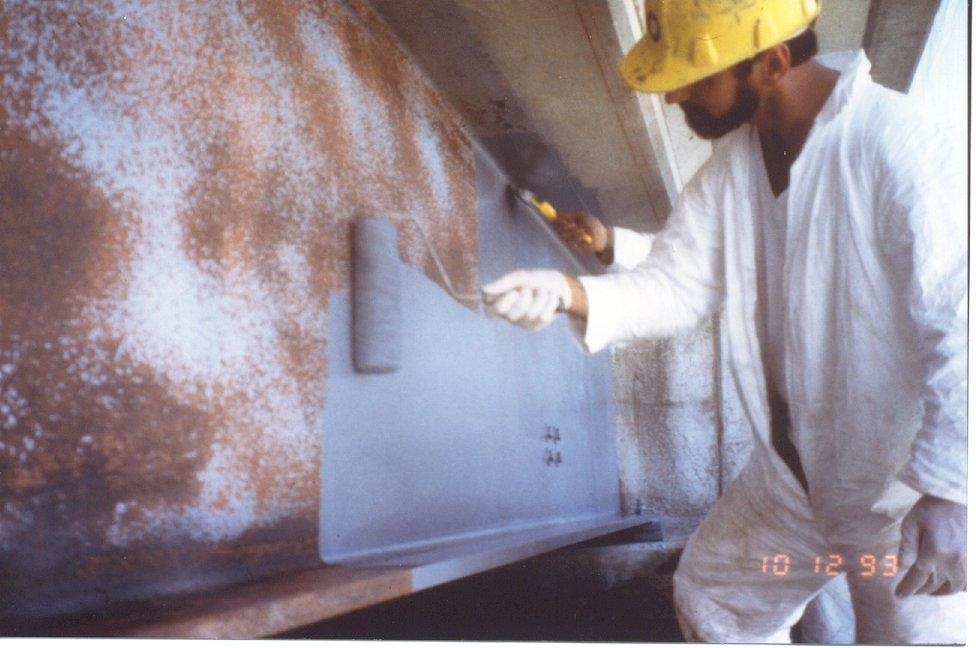

Aluthane MCU on rusty surface

Call Paul (the Epoxy Guru) at 603 435 7199 anytime to talk more or to order these materials

Related Links:

Progressive Epoxy Polymers. Inc - HOME PAGE

Best MCU coating - ALUTHANE PAGE

- A top problem solving coating - best seller

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | cycloaliphatic system | |||

| no nonyl phenol | epoxy adduct system | |||

| multi curing agents | bulk pricing | |||

| solvent free | no Calif. sales | |||

| 2 part epoxy |

2 part poly |

|||

| apply underwater |

bubble breakers |

|||

| favorite(s) product list |

xx | data sheets |

xx | |

| PACKING - jugs/bottles |

PACKING - cans |

xx | ||

| find in non marine cat |

xx | find in marine catalog |

xx | |

| PRICES/ind/commercial |

xx | PRICES/marine section |

xx | |

| BUY online | BUY online | xx | ||

| home page | xx | contact page | xx |

Quick Buy -- ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now

GOOGLE SITE SEARCH - Click here

Return to home page - index of other help projects page

Sponsor Links:

the "Epoxy Guru"

Paul Oman - MS. MBA

A.K.A. “Professor E. Poxy” -- "The Old Goat" -- "Epoxy Guru"

epoxies since 1994

Member: NACE (National Assoc. of Corrosion Engineers)

SSPC (Soc. of Protective Coatings)

Email The Epoxy Guru, or call him to talk or purchase products mentioned:

Call

603 435 7199 anytimeSponsor Links:

please support our sponsors!

|

ONLINE PRODUCT CATALOGS PROGRESSIVE EPOXY POLYMERS, Inc |

|

|

ONLINE STORE Purchase Here ------ or CALL 603 435 7199 ------ HOME PAGE |

|

|

Marine Catalog |

|

*

home

page of marine catalog section (blue background)

|

|

|

Section One

MARINE - CLEAR EPOXIES

Section Two FILLERS THICKENERS ADDITIVES

|

|

|

MASSIVE BOAT HOW TO - ISSUES - HELP WEB LINK SITE |

|

|

Residential / Commercial / DIY Catalog |

|

*

home

page of residential/commercial catalog section (brown background)

|

|

|

Section A

EPOXY PAINTS

|

|

|

WEB

EPOXY

FLOOR ISSUES LINKS SITE --- WEB EPOXY REPAIR LINKS SITE |

|

|

-------

BY SUBJECT

INDEX HELP SITE |

|

|

top selling favorite products for your every need Buy Talk Chat Support EMAIL or 603 435 7199 American manufactured, distributed, and sold epoxies and coatings. Your business helps small American Family Businesses - Thank You! |

|

Marine 1 Page Product/Price list --- for Marine Catalog |

|

--- for

DIY/Commercial

Catalog |

|

// Boat Links // Floor Links // BUY online |

(QUESTIONS, ORDERS, ETC. WE CHECK EMAILS MULTIPLE TIMES EACH DAY AND ON WEEKENDS/HOLIDAYS)

Need More?

Ask the EPOXY GURU

Ask Professor E.Poxy

|

Let's stay connected. It's a win-win situation. Receive our online NEWSLETTER by emailing us your name and email address. |

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option.

RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

the "Epoxy Guru"

Paul Oman - MS. MBA

A.K.A. “Professor E. Poxy” -- "The Old Goat" -- "Epoxy Guru"

epoxies since 1994

Member: NACE (National Assoc. of Corrosion Engineers)

SSPC (Soc. of Protective Coatings)

Email The Epoxy Guru, or call him to talk or purchase products mentioned:

Call

603 435 7199 anytime